Metal Filtration Systems

The pioneer in Melt Filtration Technology is also your metal filtration systems source. For optimal metal cleanliness, SELEE® can provide the system, filters, operational practices, metallurgical services, and support.

Let the experienced team of SELEE® engineers Analyze, Service, and Design your metal filtration system.

SELEE® can provide you with individual system components or a complete package to meet your filtration needs.

Filter Bowls/Boxes

SELEE’s precision-engineered filter bowls are unique. Their development and design are based on our own metallurgical engineers’ years of experience in the field of aluminum melt filtration and molten transfer technology. SELEE® utilizes an innovative fused silica material in the designing the filter bowls. The filter bowls can be ordered as Single, Duplex, Triplex, or Staged. They can also be custom-designed to meet our customers’ metal filtration requirements.

FEATURES AND BENEFITS:

• Thermal-shock resistant

• Easy to clean due to design

• Non-wetting for longer life

• Corrosion resistant

• Insulating

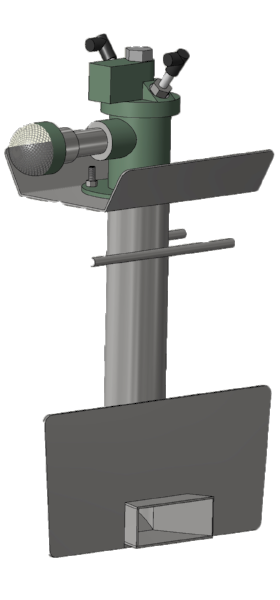

HIGH VOLUME BURNERS & WITH TEMPERATURE CONTROL

FEATURES AND BENEFITS:

- Cost Efficient

- Compact

- Portable

- Available with or without air supply valves

- Excess Air Design • Models available that meet US, European, and other International Standards

- Filter Ready” light

- Excellent heat distribution at Proper Temperature

- Can be designed to fit in the filter bowl outlet

- Stable Operation

Troughs/Launders

Our Troughs and Launders use Fused Silica and are non-wetted to the molten aluminum alloys, which is a result of our use of proprietary non-wetting additives.

FEATURES AND BENEFITS:

• Corrosion resistant • Insulating

• Thermal-shock resistant

• High Strength

• Lower Thermal Diffusivity

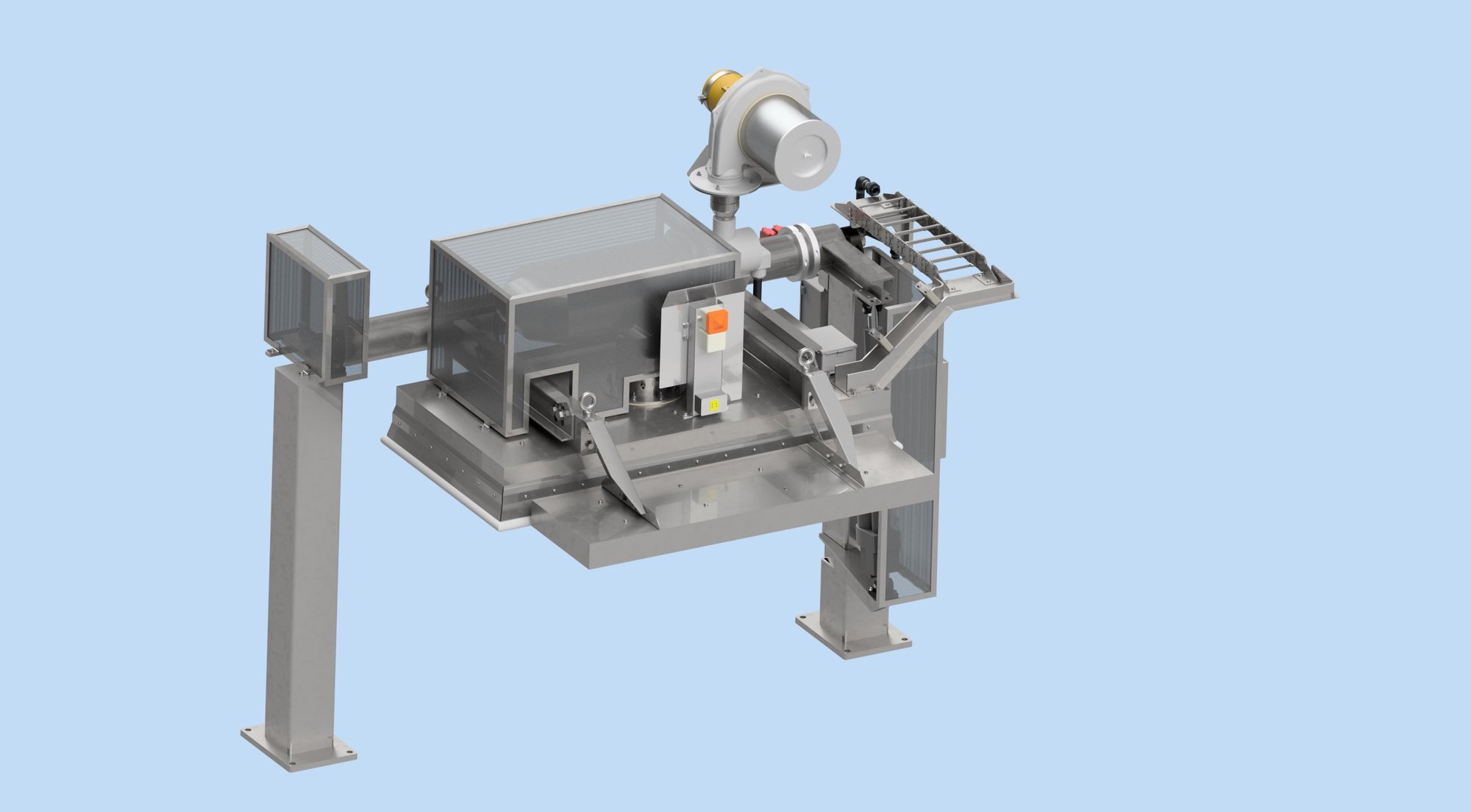

LIG ULTRA SERIES

SELEE LIG Ultra Series preheat lid systems have the following features and advantages:

- Automatic filter system startup – less human error/improved safety/increased productivity

- Burner status display including fault diagnostics

- Ethernet connectivity for SCADA data collection and remote access, use of startup permissives

- Excess air burner with air modulation control

- Digital temperature control and over temperature protection

- Rapid and uniform filter preheat via convective heat transfer

- Programmable multiple set point temperatures

- Wide burner turndown range