EXPERTS IN METAL FILTRATION

As pioneers in metal filtration, SELEE continues its legacy of helping customers improve the quality of their products and the efficiency of their operations.

Aluminum Cast House

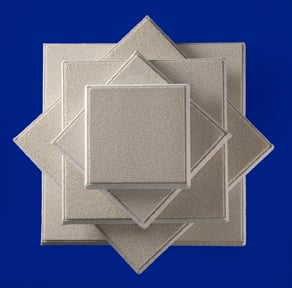

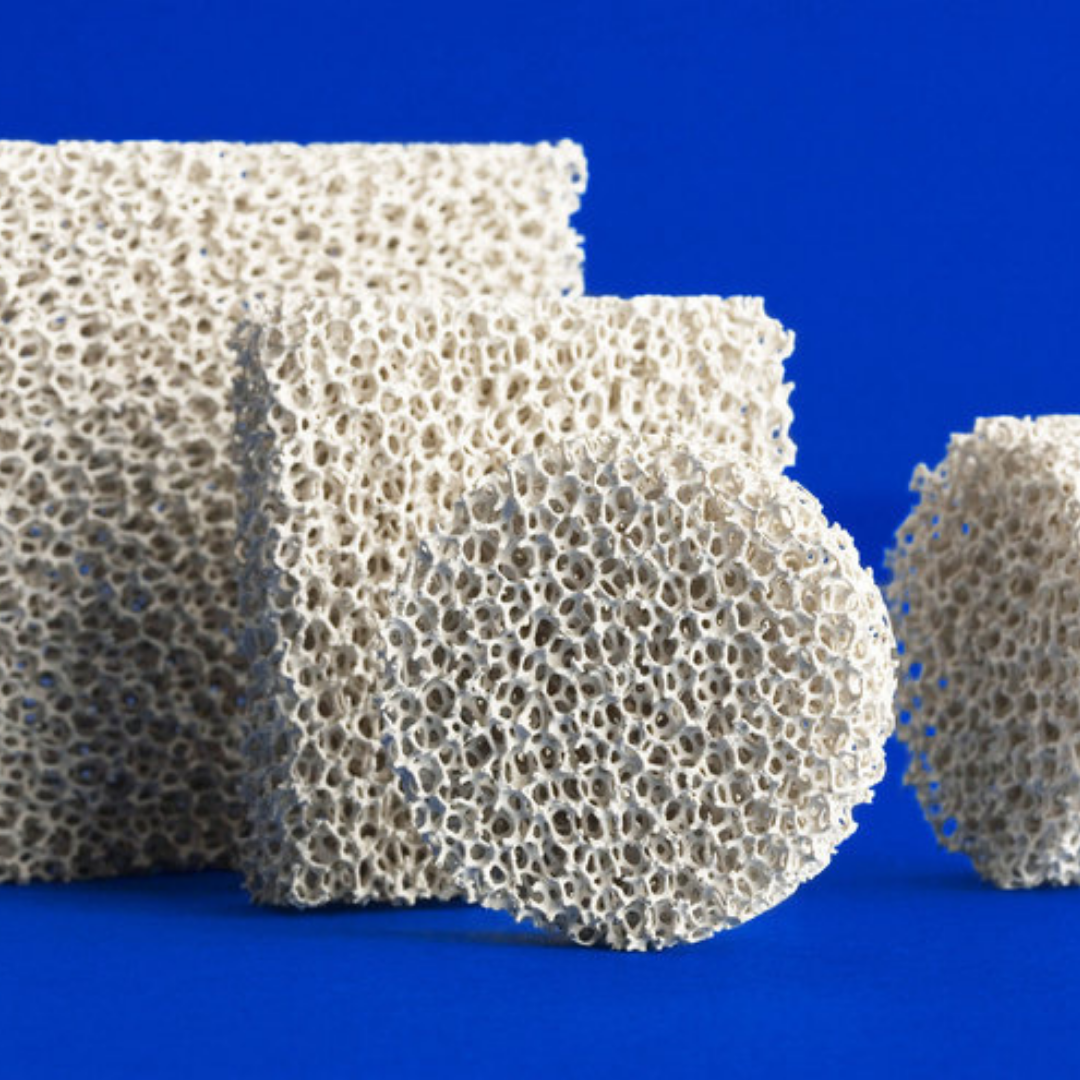

The Ceramic Foam Filter (CFF) of SELEE® structure was the first cost-effective media to remove non-metallic inclusions from molten aluminum.

Foundry

Ceramic Foam Filters (CFF) of SELEE® structure are preferred by aluminum foundries of all types and levels of production due to their superior dimensional control.

Investment Casting

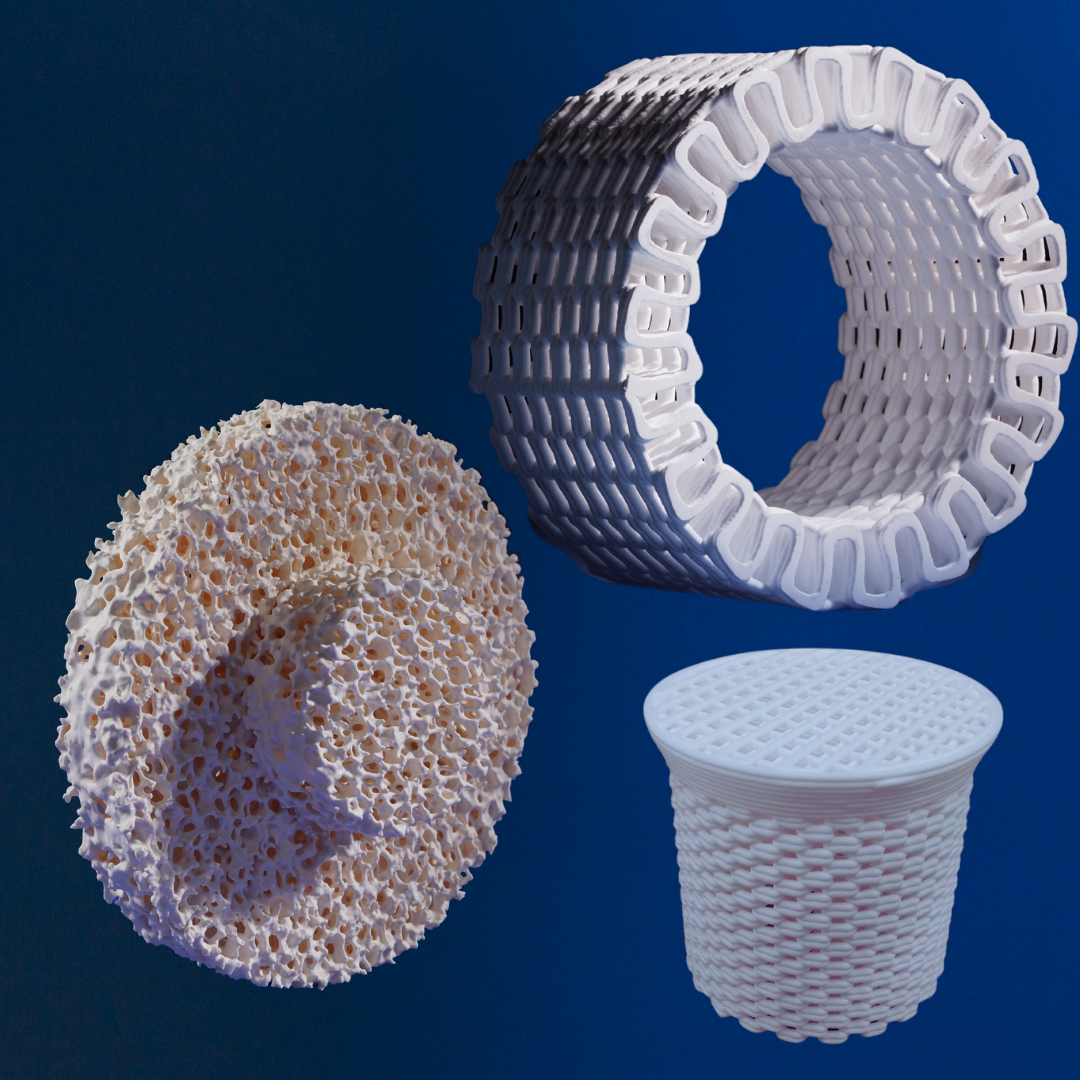

SELEE has the right ceramic filter composition for any metal you may pour in your investment foundry. Custom made for your specific application, our investment casting filters can be supplied in a wide range of sizes and shapes.

ISO 9001:2015 Certificate

.jpg?width=2000&name=Selee(56).jpg)

Metallurgical Services

At SELEE, we do much more than just sell products. Our team of world class engineers stands ready to assist you in all facets of molten metal processing, insuring that you have the knowledge you need to consistently produce the highest quality products with optimal cost efficiency.

.jpg?width=2000&name=Selee(53).jpg)

The Pioneer and World Leader In Metal Filtration Technology

SELEE pioneered the use of ceramic foam technology in metal filtration. As a result of this commitment to innovation, SELEE remains consistently at the forefront of the latest developments in filtration, melt treatment and transfer processes for molten metals of all types.

We are very proud of our long term commitment to customer service, product quality, leading edge innovation, and technical support for our customers.

Our Mission At SELEE®

OUR MISSION AT SELEE® IS TO BE THE MOST RESPECTED AND INNOVATIVE SUPPLIER ENABLING OUR CUSTOMERS TO CREATE ADVANCED METAL COMPONENTS FOR THE TRANSPORTATION, AGRICULTURE, AND CONSUMER PRODUCT INDUSTRIES.

Download Our Latest Case Study

Learn how our included Metallurgical Services helped save a client almost $100000 in scrap cost.