Foundry

SELEE products for metal filtration in foundries are as varied as the metals for which they are designed. Compositions are based on silicon carbide or aluminosilicate for iron and aluminum filtration and high-purity zirconia for steel.

ALUMINUM

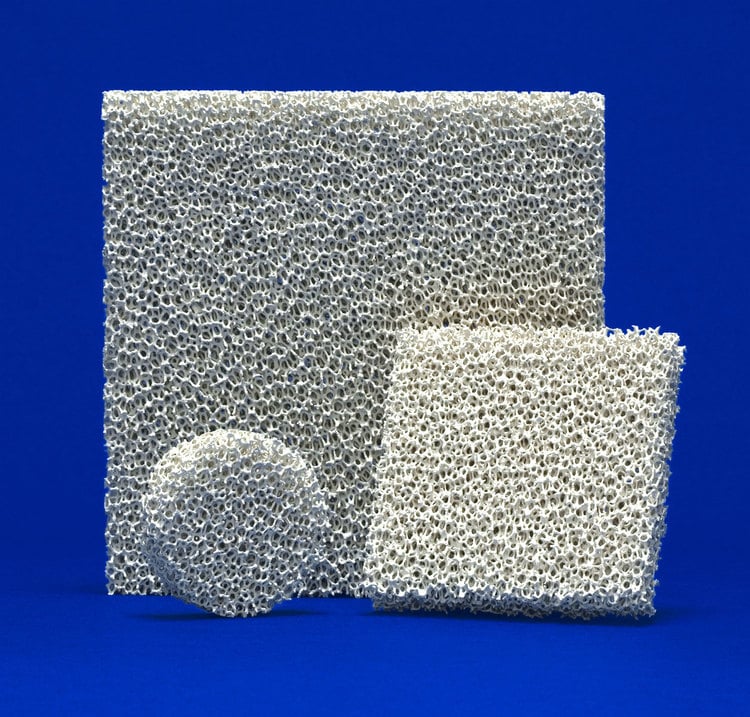

Ceramic Foam Filters (CFF) of SELEE® structure are preferred by aluminum foundries of all types and levels of production due to their superior dimensional control.

They are manufactured in a range of compositions and sizes to suit the varied processes and equipment used in the aluminum foundry.

Whether your foundry produces standard aluminum castings or critical, complex, thin-wall aerospace castings, we have the optimal formulation for your application.

IRON

The filtration and treatment of grey and ductile iron receive special attention at SELEE Corporation. SELEE is proud to show its commitment to the iron industry with a continued focus on product improvement and new product development.

The superior dimensional tolerances of SELEE® filters for iron filtration are recognizable at first glance. These filters are precision cut after firing to the tightest dimensional tolerances in the world. All surfaces, including the cut sides, have the desirable open-pore structure of true ceramic foam. The high internal surface area of this structure makes for a deep-bed filtration effect throughout the thickness of the filter. Through deep-bed filtration, even highly fluid slag is retained in the foam network, significantly reducing scrap and machining.

SELEE produces two different formulations to meet the most demanding applications, and can produce filters in a wide variety of sizes and in several thicknesses and pore sizes to meet the filtration requirements of grey and ductile iron foundries.

STEEL

To meet the demanding requirements of steel foundries, SELEE Corporation recommends the Zirconia (PRZ) filter.

Our PRZ filters are formulated of a magnesia-stabilized zirconia, the perfect composition for filtering steel grades from carbon to stainless.

There are many benefits to the steel foundry including fewer reoxidation and subsurface defects and a higher casting yield. They are highly thermal shock resistant, a must for the steel foundry.

PRZ filters are available in many standard and custom sizes, shapes, and pore sizes.